In production/assembly lines with great diversity, to verify the product specifications

Litma Technology

We create efficient automation and software solutions to ensure quality service and processes for our customers.

About Litma

Litma started its operations in 2015 incorporating the automation potential and computer vision to the development of innovative solutions, training and consultancy to the Industrial Automation Market. Our office is located in Florianópolis - SC, Brazil.

Our business deals with the production demands as unique situations while our engineering team addresses the integration of softwares and high-quality hardware components.

The outcome are reliable and robust solutions in Industrial Automation that results in great returns to the investment by maximising efficiency. In the last 3 years, Litma developed solutions on a big scale for continuous production lines inside modern factories in highly competitive sectors of the Brazilian industry.

The operation's success is achieved not only by the work of Litma's team, but also by the participation of our strategic partners, such as Acate, Greylogix, and VM Projetos.

Our solutions are the answer for the Quality Assurance needs in production lines, where is necessary:

-

Checks for absence or presence of components

-

To mesure statistics by sampling

-

To solve situations resulting from human operator fatigue

Equally, our solutions for Assembly Lines deliver a consistent response to the traceability needs of our clients.

Industrial Automation Solutions

Litma's solutions seek to harness the benefits of Industry 4.0 by transforming processes and taking automation to a higher level than the current industry.

The core of this transformation is supported by new Connectivity concepts, Artificial Intelligence, Data Science, Big Data, IoT, Machine Learning, by allowing communication between tools and solutions, and using data to optimize the production processes to deliver a more agile, autonomous and cost-effective Industrial production.

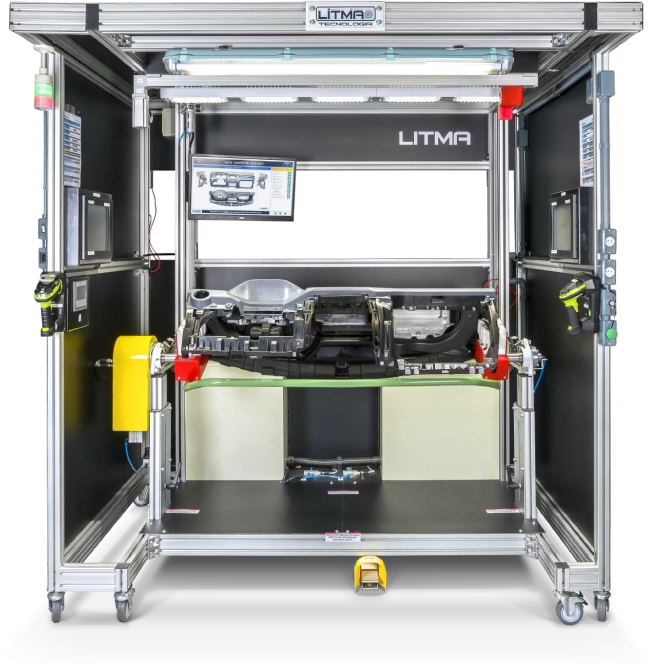

Inspection Workstation

Our Workstation seeks to guarantee compliance in components assembly and version validation (i.e colour, items, add-ons), allowing the total control of integrated devices. Works with:

- Integration with the Factory systems;

- Autonomous operation or with manual operator support;

- Results presented in a logic and intuitive style;

Inspection Portal

The Inspection Gateway is a system installed in continuous production lines, where the products are inspected while moving and without the need of human intervention.

Laudit

The Laudit is the Quality Traceability system developed by Litma that captures images and data of all the inspected products by our solutions. The data, which can be accessed anytime, bring security and comfort to our clients as it serves as evidence in case of eventual complaints about the product quality or manufacturing.

Automation and Productive Workstations

The Productive Workstations and Solutions designed and developed by LITMA Tecnologia integrates industrial devices into the equipment while preserving the specifications for digital transformation and for a smart-factory ready.

The team's expertise gives us the confidence to deliver the ideal solution to customers.

Benefits

Industrial Automation with total workstation control, allowing:

- Inspection for components assembly;

- Inspection of the Items manufactured version;

- Traceability;

- Automated movement for the inspected piece;

- Integration with manufacturing systems;

- Piece locking at the inspection (POKA-YOKE);

- Data presentation in a smart and intuitive style for operators.

Identifiable defects:

- Absence of components;

- Incorrect assembly;

- Tolerable limits for color and hue.

Our Clients

Our customers are companies of global reference in their respective sectors that are characterized by high standard demands, both in the developed solution and in the resulting traceability. For example, one of the LITMA's clients has 18 installed workstations where 2,5 millions components inspections are made per year. These are inspections that are no longer carried out manually by operators (full automation) and now have a complete record of evidence.

Contact Us

Have any questions? We are here to help. Send us a message and we will contact you.

Contact Site

Litma started its operations in 2015 incorporating the automation potential and computer vision to the development of innovative solutions, training and consultancy to the Industrial Automation Market. Our office is located in Florianópolis - SC, Brazil.

Contact

+55 48 3067 7610

+55 48 9 8857 6666

contato@litma.com.br